Architectural Columns

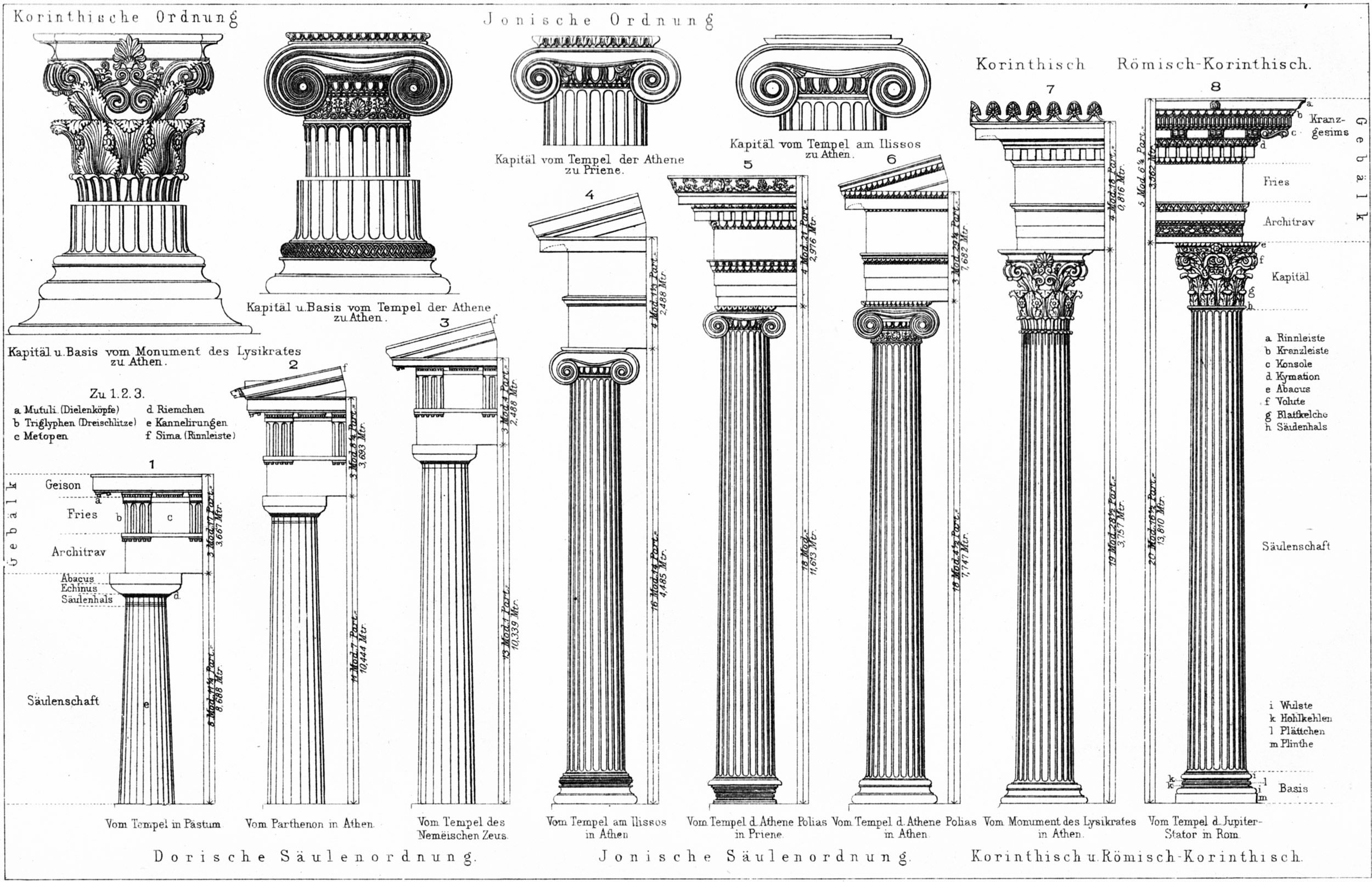

Column Styles

At FineHouse we have been supplying columns to builders, landscape pro's, and homeowners for over 20 years, hence our credentials for taking an informed look at the market for manufactured columns today.

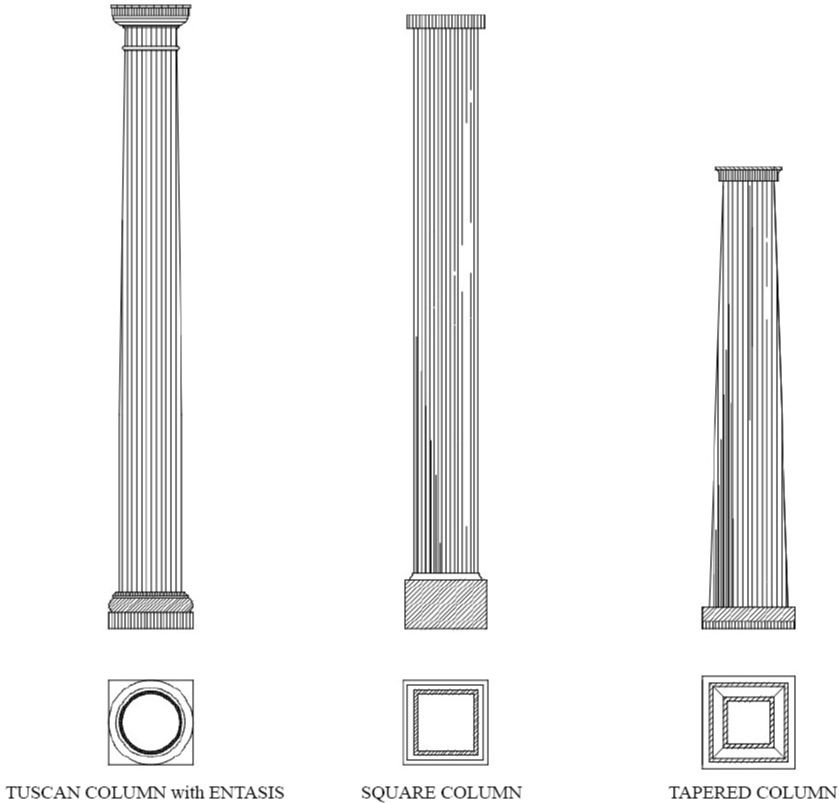

The most popular styles today would be square, round with taper, and square tapered.

Square columns are by far, the most widely used columns throughout the country, probably because they work architecturally with almost any house style; traditional, contemporary and many vernacular home styles can work with square columns. Square columns can come with different base and capital configurations ie. Tuscan, or just simple trim done in different ways. Square columns are also available in fluted as well as paneled iterations.

Another category of square columns is the tapered column. This design is often found in an Arts & Crafts or Craftsman style home, and increasingly in subdivisions by the larger home builders.

Round tapered columns are a standard in colonial homes and are prevalent in many areas of the country where traditional homes are found. Round columns are most often tapered (or with "entasis"), though they are sometimes seen in commercial or contemporary settings with no taper, just cylindrical. Round columns are also available fluted, though more in aged structures vs new construction as they are more costly, and somewhat design specific.

Freestanding, Outside Corner, Pilasted, and Inside Corner

Typical Applications ~ In Plan

Types of Manufacture

The most common columns that are factory made include; cast composite, pultruded, cellular vinyl, and FRP. Site built columns are most often made with either wood or cellular vinyl (Azek type of material).

While wood columns were popular for many years, they are no longer widely used due to cost and the fact that they do not endure outdoors like their modern counterparts.

Pultruded fiberglass columns are typically the most cost effective square columns on the market, and are very durable in outdoor use. They most often come with Tuscan capitals and bases. Pultruded columns are not suitable for splitting due to their thin wall. When painted, they are indistinguishable from a wood column and have admirable structural qualities.

Cast composite may be the most common column in use today due to their wide selection of styles, durability, and structural properties. These columns are typically made with a mix of fiberglass, marble dust, and polyester resin. They are available in round tapered, non tapered, fluted, square, and many variations of these. Cost is very reasonable considering the lifetime durability, and structural qualities these columns afford. They are reasonably easy to cut in the field to either split or cut to height with a circular saw. These can also be ordered split from the factory. Pricing increases dramatically when going beyond 12" in girth.

GFRP or FRP for Glass Reinforced Polymer are widely used for large format and split column applications. The selection of styles is less attractive here, their principal benefit is large size at a reasonable cost. Customization is another benefit as these are often made in shops that offer a range of fiberglass fabrication services.

Beyond the Basics

The material presented in this post just touches on the basics of architectural columns.

In future posts, we will cover some of the more detailed issues surrounding columns including; installation, foundations, fastening, and more.

To learn more today, visit

Architectural Columns